draw a 3d steel building

3D Printing: The Future of Construction

Published on January 31, 2022 by Jamie D.

In 2004, Professor Behrokh Khoshnevis of the Academy of Southward Carolina attempted the kickoff 3D printed wall. Since then, this innovation has exploded and it's now possible to build a house in just xx hours! The professor developed an FDM 3D printer, mounted on a robotic arm, that extrudes concrete layers instead of plastic to create a 3D model.

This Contour Crafting technology demonstrated all the qualities needed to use additive manufacturing on construction sites: reduction in costs and waste, faster structure speed, reduction of accidents, complex architectural shapes, and more. His discovery marked the start of 3D printing in construction. Nonetheless, it remains much less used than certain sectors such as helmsmanship or medical.

Big scale, industrial concrete printers tin create whole house structures autonomously.

Construction giants are apace realising the potential of of 3D technologies and their touch on the future of structure. The concrete 3D printing market is expected to reach $56.4m in 2021, and with proficient reason. More and more than companies are starting up in the sector to create new, innovative projects. Some are more futuristic, some are very real in the present, such as Apis Cor's 3D printed business firm in 24 hours. 3D concrete printing is developing rapidly and relies on different technologies and materials, offer many benefits to its users. The tech is still in its infancy however and is bound by current limitations.

What 3D printing processes in the construction sector?

i – Robotic Arm Extruders

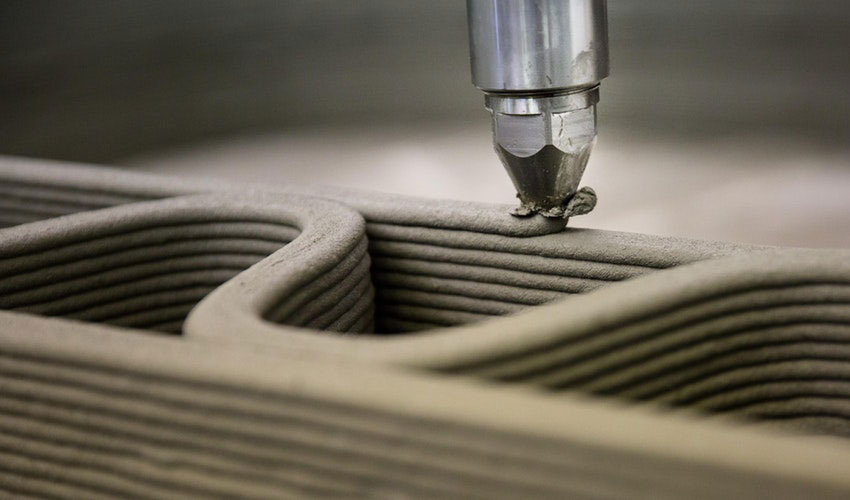

The Contour Crafting method involves the building material being deposited to create a large-scale 3D model with a smooth surface finish. Runway are installed effectually the building basis that will deed as a structure to directly the robotic arm. It moves dorsum and forth to extrude the concrete, layer-by-layer. Trowels placed on the side and above the nozzle to flatten the extruded layers and ensure the model'due south strength.

In this process, conventional concrete cannot exist used as it would need to harden before you could go along the process. If it was 3D printed it therefore wouldn't be able to support its ain weight. Therefore, concrete is used with quick setting properties.

Contour Crafting (visitor with the same name as the method) are very discreet nearly their progress. Chinese construction company WinSun Ornamentation Engineering Co describes it equally able to "steal the show" however. These machines are huge (32m long, 10m wide and 6.6m alpine). This enables them to 3D print full structures and assemble them on the spot. This is washed through mixing concrete and glass fibres on-site and then printing. This feat made made builders and construction workers enlightened of condiment manufacturing.

Constructions-3D are a competing visitor who are as well trying to 3D print large physical buildings using this tech.

Competing Companies

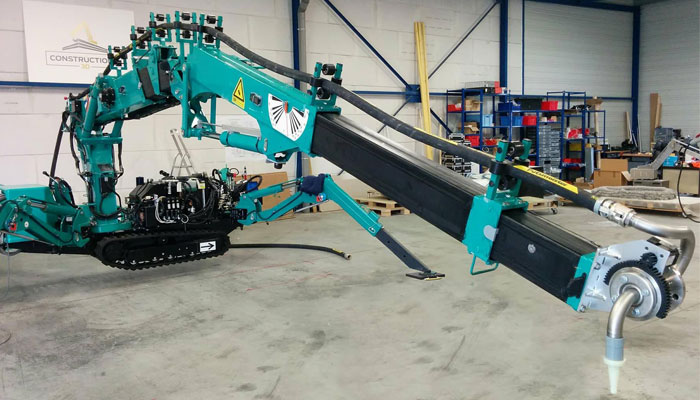

The unlike market players have adult machines using a variety of different technologies to 3D print concrete. French company Constructions-3D accept created a polar 3D printer which prints whilst inside the structure site, and then leave through the front door of the building once construction is finished. Information technology consists of a mechanical base, and robotic arm with a nozzle for extruding the material at the end. This arm offers a printable surface area of more than than 250 1000² and over 8 metres loftier.

Cazza Construction'southward robot is similar to this, involving a mobile crane arrangement assuasive them to 3D print a far wider area and create larger and taller structures. This is shown in past prints from companies like Apis Cor and XtreeE, quickly creating whole houses.

Other companies have specialised in extruding materials other than physical with this engineering science. BatiPrint 3D's patented procedure is a striking case: the Academy of Nantes, Bouygues Construction and Lafarge Holcim joined forces to develop an industrial robot that prints 3 layers of fabric at once. 2 of these layers are a polymeric cream, with the 3rd layer being concrete.Benoit Furet, professor at the University of Nantes explains "the cream brings inner and outer insulation; concrete and reinforcement the antiseismic begetting structure. "

Batiprint 3D are a French company aiming to 3D print large structures.

two – Sand layers linked together

Italian architect Enrico Dini first fabricated waves as 'the human who 3D prints houses.' More recently, he demonstrated an interesting 3D printing process using his 'D-Shape' 3D printer. This automobile relies on the binding of powder which makes information technology possible to solidify a layer of material with a folder. Layers of sand are deposited according to the desired thickness before a impress head pours droplets (the binder) to harden the sand. This iv x four metre car can create large structures of up to 6 cubic metres in size.

The print site where the D-Shape will 3D print a physical construction.

3 – Metal for solid structures

Dutch company MX3D have developed a unique structure method called WAAM (Wire Arc Condiment Manufacturing), which enables you to 3D print metal structures with a 6-axis robot that drops 2 kilos of material per hour.

This robot was the event of collaboration with Air Liquide and ArcelorMittal and is equipped with a welder and a nozzle to weld, layer-by-layer, metallic rods. This process is too uniform with other metal allows such as stainless steel, bronze, aluminium and Inconel. The machine tin can be likened to a sort of giant soldering iron. The squad commented that"we combined an industrial robot with a welding machine to turn it into a 3D printer that works with our own software."

MX3D are i of a number of innovative startups in the 3D printed house sector.

Though conceptualised past startups, these projects frequently require support by bigger names in construction. The Imperial BAM Grouping partnered with Eindhoven University of Technology to pattern a 3D printed physical bridge for cyclists. In add-on, Bouygues Construction turned to 3D printing to build houses in the Lille, France. Moreover, Vinci Construction partnered with French startup XtreeE to test the construction of complex structures, and Swedish group Skanska recently collaborated with the University of Loughborough to develop a 3D concrete press process.

"we combined an industrial robot with a welding machine to plow it into a 3D printer that works with our own software," – MX3D team.

Why use 3D printing in construction?

Firstly, 3D printing concrete saves a lot of fourth dimension. In detail, using these technologies potentially reduces a 2 week task to just three-4 days. Moreover, this reduces risks of injury at piece of work. Benoit Furet at the Academy of Nantes explains"the reduction of the hardship and the risks is a reality, nosotros realized rays of 3.8m of summit without whatever scaffolding. In addition, the structure site is very quiet."

His team managed to impress in 3D a 95m² firm, and the starting time 3D printed social housing in the city. Benoit says their BatiPrint technology has also made it easier to create curved shapes at a lower cost. Moreover, every bit 3D printers don't need to swallow or sleep, they don't stop working until the projection is finished. This greatly reduces waiting times.

Advantages of 3D printing in construction

In terms of materials usage, 3D printing is economical. With additive rather than subtractive processes, less materials are used than traditional manufacturing processes. This reduces the environmental touch on as less waste product is produced.Romain Duballet, ane of the co-founders of XtreeE, explains "with an increased geometric mastery, nosotros can build optimized shapes to limit the amount of materials used."

However, there are still caveats to the dream of 3D press houses, bridges and skyscrapers. Axel Thèry of Constructions-3D explains that"the main difficulties come from the fact that the process of 3D printing buildings is not today recognized as a construction method past many codes and standards bodies. As the printed structures are non traditional, the calculations of resistance and resistance in fourth dimension are hard to realize, that is why the habitable works volition have to be tested on a case by example basis at the beginning." These standards bodies are concerned whether these structures are actually solid and if they can withstand their environments.

Constructions-3D's machine resembles a huge tractor, and 3D prints concrete to make large structures.

3D printed house: a solution to the housing crisis?

Since 3D press now allows structures to be created more rapidly, it is ideal to combat the housing crunch. Some companies are gravitating towards additive manufacturing as a result. This includes Italian company WASP, which aims to build a more sustainable globe through 3D printing. They have developed one of the world'south largest 3D printers which is capable of edifice homes from locally sourced materials using solar, wind, or hydro power. This enables regions that don't withal take access to electricity to 3D print environmentally friendly structures with local resource.

WASP 3D printers at piece of work to create a hereafter where environmentally friendly materials create 3D printed houses.

Similarly in Brazil, Anielle Guedes founded Urban3D to answer to Brazil's housing crisis. Her visitor 3D prints parts of buildings in a defended manufactory before assembling them on-site. This enables her to create buildings of a superlative that is not possible if 3D printing was done on-site. The visitor is currently testing several prototypes and hopes to provide a solution to the development of Brazilian shantytowns.

Russian company Apis Cor is also convinced of the positive bear upon that 3D press can take on housing. Founder and CEO NikitaChen-iun-tai explains, "we believe that additive manufacturing is an effective solution confronting the housing crisis and that is why nosotros have developed our project. Nosotros promise that in a few years this approach volition be thoroughly tested in unlike parts of the world to demonstrate its feasibility. We believe that more and more structure companies will adopt this engineering science, as it is already the case for some today."

Russian company Apis Cor built this business firm in just 24 hours using their concrete 3D printer.

3D Printing in Infinite?

Additive manufacturing could also be a way for humanity to explore infinite. NASA has launched the '3D Printed Habitat Claiming' examining technologies used to build homes in space, such as on the Moon or on Mars. Although ambitious, it is likewise early to tell if 3D printing is a feasible solution. We tin tell nevertheless, that 3D printing in construction is to get a very real global force. SmarTech Publishing recently published a report predicting global revenues in the sector to be $40bn in 2027. To go from a few million dollars to $40bn in 10 years is astonishing. Therefore, nosotros volition have to run across how the world reacts to this tech in the hereafter.

Did you savour our characteristic story on 3D printing in construction? Let u.s. know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

Source: https://www.3dnatives.com/en/3d-printing-construction-310120184/

0 Response to "draw a 3d steel building"

Post a Comment